In search of lithium

Exploring geology, electric vehicles, and a short history of Cornish mining

“Cornish lads are fishermen and Cornish lads are miners too. / But when the fish and tin are gone, what are the Cornish boys to do?”

- Cornish Lads, by musician Roger Bryant

Some say there is mining in their blood.

This much is immediately evident from my excursion to Redruth, a town and civil parish in Cornwall, where I am greeted by a two-metre-tall bronze sculpture of a Cornish tin miner on the High Street. Later, I came across Tinners Hounds; sculptures dotted across the town that are made from the discarded boots of former local miners.

Mining in Cornwall and Devon, in the southwest of Britain, began in the early Bronze Age, around 2150 BC. The most commonly extracted metals during this period were tin and copper.

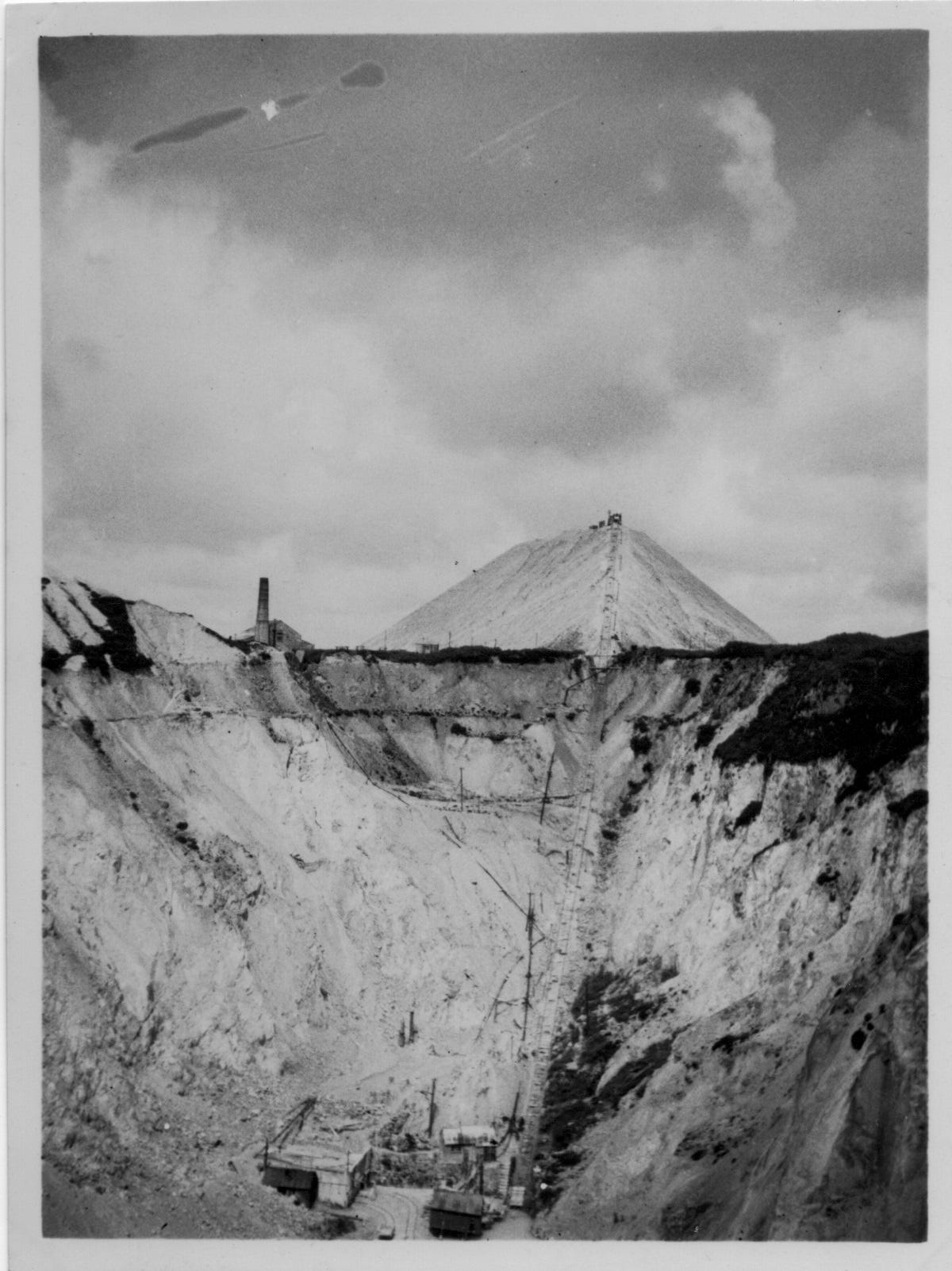

The discovery of kaolinite clay deposits, also known as china clay, in southwest England in the mid-1700s launched the country's porcelain industry. Kaolin is a soft, white clay that was first used by the Chinese, who developed techniques for using it to make porcelain in the 7th and 8th centuries AD. The china clay deposits in Cornwall are still the largest in the world, and 120 million tonnes of china clay have been extracted to date. The impacts of china clay mining on the Cornish landscape are still visible several hundred years later.

During the 18th century, Cornwall was the mining centre of the world. In the early 19th century, Cornwall was the greatest producer of copper specifically. At its peak, the copper mining industry employed roughly 30 per cent of Cornwall’s male workforce. When copper deposits had been exhausted, tin took over. Cornwall didn’t run out of tin, but large finds of deposits abroad meant that Cornish mine owners could no longer financially compete with the increasing supply, so local mines were closed in the 1890s, giving rise to the ‘Cornish diaspora,’ as miners left Cornwall to seek their fortunes in other mining areas across the world. This mass emigration shaped modern Cornwall. According to Cornwall Heritage Trust, “In each decade from 1861 to 1901, about a fifth of the Cornish male population migrated abroad – three times the average for England and Wales. In total a quarter of a million people left Cornwall between 1841 and 1901. Miners made up most of the numbers.”

The Cornish miners were known as ‘Cousin Jack’ at home - thought to be about “the immensely popular 18th- and 19th-century hero Jack the Giant-Killer, whose tale tells how he came from West Cornwall, killed a giant by excavating a large hole into which he fell, and was known on occasion as 'Cousin Jack' when away from home.” Mining was dangerous, precarious work, but it built Cornwall in more ways than one, and put the county on the global map.

Mining relics pepper Cornwall; monuments to a rich history that elevated many a Kernowyon (Cornish for ‘Cornish people’) out of poverty. I visited the East Pool Mine, which is now situated at the end of a Morrisons supermarket car park. East Pool Mine is an industrial heritage discovery centre built around historic Cornish beam engines.

It still stands tall, with steam-powered engines on display. The advances in steam technology at the time were made available by Cornish engineer and inventor Richard Trevithick. I visited Trevithick’s home too; a thatched cob cottage built in 1700 that still houses tenants. “Have you noticed that inventors always come from cottages like this?” a resident asked me as I admired the dwelling. “They’re never born in mansions. They always come from houses like this. Small cottages.”

I asked him what he thought of new lithium mining projects in Cornwall. “Good idea,” he said simply.

The increasing global need for lithium

Lithium is a soft, silvery-white alkali metal that was discovered in 1817 by Swedish chemist Johan August Arfwedson when he investigated petalite, one of the first lithium minerals to be discovered. He identified an unknown metal, which he called lithium, from the Greek word for a stone, lithos.

There are three main sources of lithium in nature: pegmatites, brines, and clays. Put very simply, these involve crushing rock to extract lithium ore (which is highly energy-intensive and expensive), or leaving pumped groundwater to evaporate and creating chemical reactions with the brine to produce lithium minerals, respectively.

I’m sure it all sounds rather abstract, but if you’re reading this, your lifestyle is dependent on lithium. Before electric cars came on the market, lithium was already mined for many uses, including cosmetics, shock-resistant glass, aluminium foil, and medications for conditions ranging from gout to mental disorders. Lithium is used in rechargeable batteries for mobile phones, laptops, digital cameras, and electric vehicles, and in non-rechargeable batteries for heart pacemakers, toys, and clocks. Lithium keeps grease running at arctic temperatures, treats myriad health conditions, and is a key element in the global energy transition and fight against climate change.

The current growing demand for lithium is mostly due to the need for batteries for solar panels and electric vehicles (EVs). Lithium is one of the key components in electric vehicle batteries, and rising demand for EVs is now straining global lithium supplies. According to the International Energy Agency (IEA), at its current rate of availability, the world could face lithium shortages by 2025.

A lithium-ion battery pack for a single EV contains around 8 kilograms of lithium. Last year, global lithium production reached 100,000 tonnes. At the COP26 climate talks, 30 countries committed to halting sales of new petrol and diesel vehicles by 2040. At the end of 2021, the number of electric cars on the road exceeded 16.5 million. Millions more are needed, and much more lithium besides.

To EV, or not to EV?

Electric vehicles are not without criticism. English actor Rowan Atkinson recently wrote that he felt ‘duped’ by EVs, arguing that “the lithium-ion batteries fitted currently to nearly all electric vehicles: they’re absurdly heavy, many rare earth metals and huge amounts of energy are required to make them, and they only last about 10 years. It seems a perverse choice of hardware with which to lead the automobile’s fight against the climate crisis.”

However, the fact that EVs require mined materials is not a legitimate argument against them. All mining exacts an environmental cost, and the overall goal is to reduce that impact wherever possible, rather than eliminate it altogether (which is not possible with our modern lifestyles). We should not throw the baby out with the bathwater, but instead need to assess where resources for green technologies come from fairly and accurately and make decisions accordingly.

These calculations have already been done. While Atkinson’s argument that emissions are higher during the production of an EV than for non-EVs is true, this environmental cost very quickly pays off when you start driving the vehicle: with the distance driven, gasoline cars emit far more emissions. Reuters calculates that after 21,000 km, battery cars start reducing CO2.

This is also evident when comparing the CO2 emissions of EVs with petrol and diesel cars over their life cycles: the emissions of an EV are lower than of non-EVs, although how much lower depends on the electricity mix being used to power them. As the global energy grid is decarbonised, these numbers will also improve.

Love them or hate them, EVs are an important part of the energy transition. We need to electrify as much of our lifestyles as possible, and decarbonise the energy grid at the same time. While EVs do, of course, have an environmental impact, they are still better than the alternatives (bar not driving at all). An argument to make alongside that is that to lower their environmental impact as much as possible, EVs should also be powered with clean energy.

There’s white gold in them hills

Which brings us back to Cornwall - and Cornwall back to mining.

The county of Cornwall has the largest known lithium deposit in Europe. Lithium was first discovered in hot springs in deep Cornish mines in 1864 by Professor William Allen Miller. Prof. Miller was sent a batch of bottles of hot spring water from beneath the Wheal Clifford copper mine, near the town of Redruth. He analysed the brine at his laboratory at King’s College London and found that it contained a large amount of lithium. “The occurrence of so large an amount of lithium invests this water with unusual interest and importance,” he wrote.

Now, a private start-up company aims to mine this battery-grade lithium.

Founded in 2016, Cornish Lithium Ltd has 70 employees and a clear vision. The company is conducting test drilling at sites at United Downs near Redruth and Trelavour near St Austell. They aim to produce large amounts of lithium hydroxide from a disused china clay mine, and from boreholes into the subterranean geothermal waters. Lithium-enriched geothermal waters can be accessed through boreholes. Once the waters have been pumped to the surface, the lithium compounds can be extracted using Direct Lithium Extraction (DLE) technologies, which enable recovery of lithium salts from the water without the need for evaporation ponds etc. By using geothermal energy to power the extraction process, the result should be zero-carbon lithium.

The granite rocks beneath Cornwall are rich in lithium and heat. In the granite are tiny black flecks in the rock called mica. This, and in the geothermal waters washing through the subterranean rocks, is where lithium is found.

In the UK, mineral rights are privately held; The Crown (‘Mines Royal’) owns gold and silver, and the UK Government owns gas, coal, and oil. When mineral rights belong to a private landowner, permission for exploration has to be given by the landowner. Cornish Lithium has secured rights to the land where they're looking to extract lithium from hard rock, in an old china clay pit, from Lord Falmouth. The advantage of taking over an existing open pit means that it is already accessible, the landscape has already been mined and is no longer in use by the public, and ultimately there is minimal impact on the local environment.

The rocks beneath Cornwall are hot compared to others in the UK, and the granite underlying the region is rich in lithium. As a result, lithium-enriched geothermal waters can be found circulating naturally through the rocks at depth. It is possible to drill a borehole to intercept these waters, pump them to surface and extract elements from the brine, including lithium. It's a significantly smaller surface footprint than hard rock mines, with minimal environmental impacts.

Using a combination of data science, 3D modelling, and satellite imaging, the company has been able to map underground deposits of lithium in geothermal waters with high accuracy and estimates that it will be able to produce between 500 to 1,000 tonnes of lithium a year from each geothermal extraction site.

Why here?

Lithium resources are concentrated in a few places and over half of today’s production is in areas with high water stress. Lithium mining can use a vast amount of water, although the method of extraction does impact water usage to some degree. Other countries with lithium include the flat desert basins of the ‘lithium triangle’ of Chile, Argentina and Bolivia. This triangle hosts some of the driest places on Earth.

According to the US Geological Survey, the world’s largest lithium producer is Australia, extracting around 40,000 tonnes a year from hard rock spodumene deposits. Hard rock mining carries a significant environmental impact, and it is highly energy intensive.

Currently, the IEA puts China’s share of global lithium chemical production at 60 per cent and says that it accounts for 80 per cent of lithium hydroxide output.

Rather than placing the burden on other countries to source our minerals – and risk mining with poor environmental standards – where possible, we should look closer to home for deposits that can help with the transition to electric vehicles.

There is growing acceptance that the method that Cornish Lithium is using – direct lithium extraction – is a more environmentally-responsible way to produce lithium, compared with some of the more water-intensive alternatives.

A geothermal project

I travelled south to Cornwall to find out more about Cornish Lithium’s ambitions. I began my tour with the United Downs geothermal test site, where I was surprised by how small a geothermal borehole is. Cornish Lithium has received funding from the UK Government to build a pilot lithium extraction plant at the site.

Cornish Lithium has drilled three research boreholes to date - two at United Downs to approximately 1km deep, and a third a couple of miles down the road to 2km deep. These have shown that there are warm, lithium-enriched waters at these depths and the company is now investigating opportunities to partner with local businesses or industries to make use of the heat potential too. While we are touching on British history, it’s also worth remembering that using geothermal energy is another old tradition, which began with Romans bathing in natural hot springs.

Lucy Crane is an exploration geologist with an MSc in Mining Geology from Camborne School of Mines and a Master’s degree in Earth Sciences from the University of Oxford. She has worked as a Sustainability Manager at Cornish Lithium for 6 years.

The supply chain for electric vehicles and solar panels is global. Crane describes a lack of transparency around how sites are managed and workers are treated abroad. Environmental and social standards are high in the UK, Crane tells me, which is why we should source as much material and undertake as much manufacturing here as possible.

Our conversation takes us from topographical granite highs, to findings at the lithium-enriched clay pit in Cornwall, to tectonic activity in the southwest of England. “It’s a bit like a volcano that never explodes,” Crane explains, before apologising for the mini geology lecture.

I am intrigued. What led a geologist to this kind of work? Crane did not originally expect to work in mining but she realised that she could do good work in this field, as the social and environmental aspects of how land is used and how people are treated are important to her.

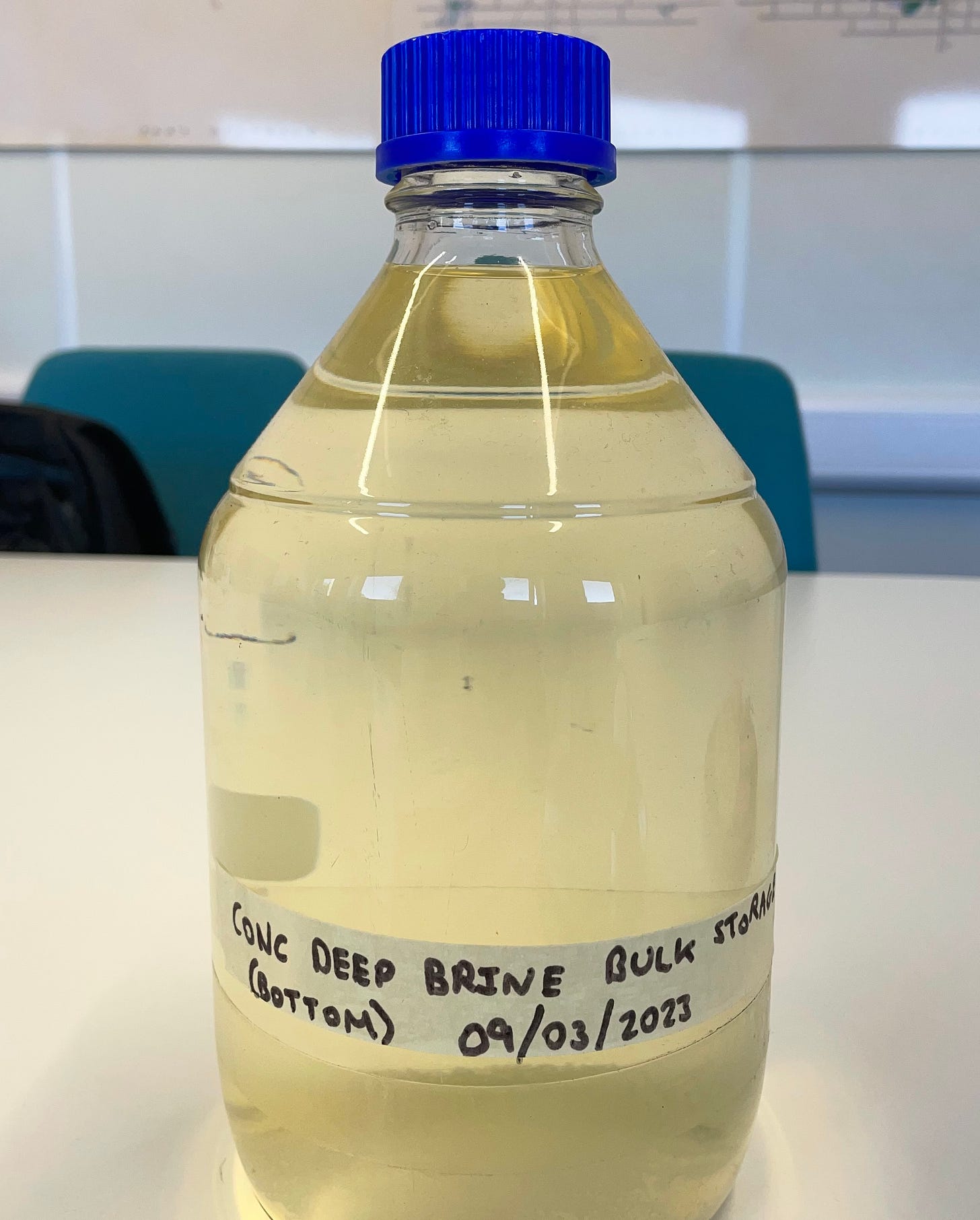

Crane’s colleague Mark Harris has a background in sewage management and describes his life in Cornwall as “like being in the Wild West.” Lithium is the lightest weight metal on the periodic table, he tells me. Harris plonks down a bottle of brine in front of me, explaining how the liquid is recovered and how the process enables them to identify the presence of lithium.

I paid a quick visit to Blackwater, where Cornish Lithium has a small drill site, as I wanted to see for myself whether it was intrusive for the local population. Instead, I found a tidy, small site, shielded with hay bales to reduce the sight and noise of the drill from the neighbouring village. “We added the hay bales after speaking to local people about how we could reduce the impact for them,” Crane told me proudly. “They are supportive of the project, but we also make sure we listen to them.”

Next, I visited the headquarters of the Trelavour project, where Cornish Lithium is making use of the existing infrastructure on the industrial site. Crane says that the aim is to extract lithium on-site and process it locally too. She calls these “important social standards….Skipping the need to take the processing anywhere else.”

Crane points out a disused rail track next to one of the buildings on the site. “We’ll be able to connect this to the grid,” she says. “That means fewer lorries on the road for transport, which is better environmentally.”

A trip to the pit

I decided to overcome my long-held prejudices against mining by visiting the former china clay mine myself and forming an opinion based on facts instead of misinformation. What I found surprised me.

We took a bumpy trip in an off-road vehicle down to the old Trelavour mine in St Dennis, Cornwall. It was an unusually hot day for England - 20 degrees Celsius in early June - and we were roasting in the direct sunlight. This area is known as Clay Country: its signature white peaks and mounds, known as the ‘Cornish Alps,’ are not naturally-formed landscapes, but the result of centuries of mining for china clay in the area.

Trelavour is a former china clay mining site in Cornwall. The landscape here is more akin to a desert than the rolling hills of the southwest that I am accustomed to. Crane enthusiastically hands me different pieces of rock, pointing out bits of copper, lithium, and more. While I see only rock all around me, she sees a world of potential.

Using an existing mining site has benefits: it is already supported by significant existing infrastructure including power, road, and rail. As I look at the winding path down to the site, I imagine working here in ordinary weather conditions – Cornwall has a wet climate. Small pools of rainwater show that the dusty rock runs into very boggy pools when it is wet. Many a worker has lost a boot here, I’m told. I wonder how people managed this work centuries ago without the technology we have access to today. Such was once the miner’s lot.

Thankfully, times have changed.

As well as this pit, the company has been able to secure land one kilometre around the site, which will help them to maintain a perimeter around it, and to keep adventurers from entering the site. Now that Cornish Lithium is working on the site, they are responsible for keeping people safe on it.

I speak to a Cornish-born employee, Eldon Douglas, who is also an ecologist. He tells me that a baseline survey is currently being undertaken to assess what needs to be done to best manage the site, which has been “left to invasive species like Japanese knotweed.” The best approach is to “look at what species you have, and then what works best for the area,” he says. “There’s no point planting something if it’s not what the land wants.”

I am surprised to find that the old mine is stunning: full of clear water and surrounded by foliage. A dragonfly lands at my feet, and I watch a tadpole swim by in the makeshift lake. “This is left over from the old mine?” I ask. My disbelief is obvious. Douglas laughs: “This is the old mine. It looks nice, but you wouldn’t want to swim in it. Some have tried, but they’ve no idea how deep that mine goes. Locals have told us that back in the day they used to dump anything they didn’t want in the old Trevalour pit, like old cars. So it’ll be interesting to see what we find when we dredge it.”

The company tests water on site every week and is removing invasive species in an attempt to rewild the landscape. Past attempts to cover the hills here with foliage have in part failed: Douglas points out a hill that they have cordoned off because the foliage growing on it is slipping down, exposing a white peak.

Douglas seems happy with the project; he has a job he enjoys here, which means that he doesn’t have to leave Cornwall to find work. He tells me that the company is admired for hiring local people and speaking to the community about what they’re doing. That the security used on site is run by a local company. “My family goes back as long as records began,” he says proudly.

An opportunity for new growth

The old saying goes: If it wasn’t grown, it was mined.

Yet mining is a dirty word to many people, and it was to me for a long time as an environmentalist. I’ve come a long way from believing that the world can be powered by sunshine alone and that all our needs can be met by tilling soil. My parents left behind a life of rice farming to take up factory work – manufacturing goods from saucepans to jewellery boxes – to escape poverty and also because they understood what makes the world go around.

Crane and I talked about current attitudes toward producing goods in the UK. “If we can’t see it, we don’t care what the impacts are,” she said. Crane has spent her life studying Earth Sciences and wants to do things in an ecologically-sound way while recognising that our need for more minerals is not going to disappear.

As an advocate for replacing fossil fuels with clean energy while maintaining our high-quality lifestyles, I am inclined to agree. One criticism I often hear about nuclear energy is that it requires mining, yet a life-cycle assessment by the IEA shows that it requires far less resources than alternatives that don’t produce energy for half as long. Even so, since the ultimate goal is to bring down global emissions, all environmentally-better options need to be explored to combat climate change while continuing to meet our energy needs.

Our lifestyles are dependent on mining. Even if we cut back our carbon footprints, we still need to build new homes, air conditioners, infrastructure for energy grids, power plants and more. All of this requires minerals, and when more of them are sourced from home, fewer are shipped or flown in from overseas, and high environmental standards can be maintained.

The town I visited is one of the most deprived areas in Cornwall, where some families have been without work for several generations. Because of this, former mining towns often have a social licence to build enterprises that bring economic growth and jobs, which other regions may lack. In Cornwall, former Independent Councillor (and ex-miner) Mark Kaczmarek has actively campaigned for mining in the area, and says: “United Downs has a long history and I would love to see mining in Cornwall restarted but it’d have to be more environmentally friendly, clean mining.”

I spoke to an 82-year-old Cornishman who has a passion for Cornish history, and a lot to say about Redruth in particular. “There’s a lot of hope in the old families here, that Kernow’s [Cornish for ‘Cornwall’] time will come again,” John told me. “It’s not all like Poldark, but you know, it’s in our blood.”

In 2020, drill sampling at the South Crofty tin mine - the last tin mine to be closed in Cornwall - found the second highest-ever grade of tin recorded in a mine. While there has been some opposition to the return of tin mining in Cornwall, many locals are keen to see it happen, and lithium appears to have broad support locally.

Cornish Lithium is not the only kid on the block, but one of several ventures exploring lithium extraction in this part of the world. British Lithium is one them, and they also aim to produce battery-grade lithium - possibly as much as 21,000 tonnes a year.

As we climbed into the off-road vehicle to leave the pit, Crane handed me two pieces of white rock. One was hard, the other soft and pliable. “Lithium is easy to spot when you know what to look for,” she said, pointing at the shiny specks in the rock. I looked at the white residue I had just crushed in my hand and considered what this project means, for Cornwall and beyond. Although these companies will not produce the bulk of the lithium the world needs, their contribution will still be invaluable, and Cornwall does have the potential to supply the UK with almost all the lithium it needs.

The clay leaves a velvet-like coat on my fingers. I think about how mining lithium in Cornwall will enable people to stop relying on petrol and diesel cars. How the lithium will end up in ordinary batteries for solar panels owned by homeowners. These projects will provide well-paid jobs, adhere to strict environmental and social standards, and continue a legacy of tradition for this part of the world. I wonder how much of an impact it will have on the local population, both economically and by providing work for local people.

Once, I would have only seen this as a piece of rock. Now, I see it differently. The word lithium may translate literally to ‘stone,’ but I can see now that I am holding more than just stone in my hand. This is the raw material. This is a key part of the future. This is core to the green transition that the world is attempting. So much depends on rare materials like lithium, and so much can be achieved if more projects like this get the go-ahead.

I do not have mining in my blood, but like the Cornish people who have high hopes for a white gold rush here, I do feel an affinity for the local lithium mining projects. I only hope that the UK, and other countries that do not experience water stress, and that hold high environmental and social standards, take up the challenge to mine much-needed rare minerals, instead of leaving it to others. Our future depends on it. Although the tin mines in Cornwall may remain closed for now, it’s clear that the demand for lithium is here to stay. Providing a new worthy giant for Cousin Jack to tackle in this part of the world, if ever there was one.

My PhD was on getting kaolin out of water suspension - at the University of Cape Town. I led a Materials Group at CSIR in South Africa that secured global patents in Lithium battery technology in the 1990s (pretty early). Subsequently had a nuclear career in South Africa and Australia.

Thank you for a very good article.

The one downside of Li is its toxicity when children swallow damaged button cells - it replaces K (potassium) that regulates heartbeat - leading to arrythmia and often death. I would like to see sealed Li battery disposal containers on the shelves of supermarkets and a closed disposal cycle. Also, advice to people on Li bicycle batteries and not charging these in homes. The fires cannot be extinguished with water - it is actually an accelerant. We should be happy living with Li batteries but treat them with respect like medicines and ammonia.

I appreciate your activism and leadership. Thanks.

These articles are so good. Lithium will be needed but I have heard more convincing arguments against EVs in their current level of development than Atkinson's. According to Bjorn Lomborg lifecycle assessments of 2/3rds less carbon and fairly equal costs assume EVs are driven twice as many kms as they actually are. The CO2 saving is still significant but the cost per saving isn't - the resources should preferentially go to other solutions at this time