"Hot water was civilisation" - Terry Pratchett

In a podcast interview this week, Meta CEO Mark Zuckerberg stated that regulations on building new energy infrastructure are holding back the development of the data centres needed to support energy-intensive Artificial Intelligence (AI).

Mark is correct: Asian countries are generally faster builders than most Western countries. Japan, South Korea, and China have built nuclear reactors in around five years. Newly built South Korean nuclear plants have also achieved speed and cost-effectiveness in construction that exceeds most other countries.

According to an Energy Policy paper, the decline in South Korean nuclear power costs is comparable to the decline in solar power costs in Germany over the same period. Building nuclear power plants in China is also seven or eight times cheaper than anywhere else. China currently has 21 nuclear reactors under construction - two and a half times more than any other country - and a new reactor costs roughly $2 billion to build in roughly five years.

The slow speed and correlative high cost of nuclear energy can be attributed to three dominant factors: over-regulation, failure to standardise, and loss of skills.

How can we do it differently? What do we need to change? Let’s begin with the pitfalls of over-regulation.

Reregulate nuclear

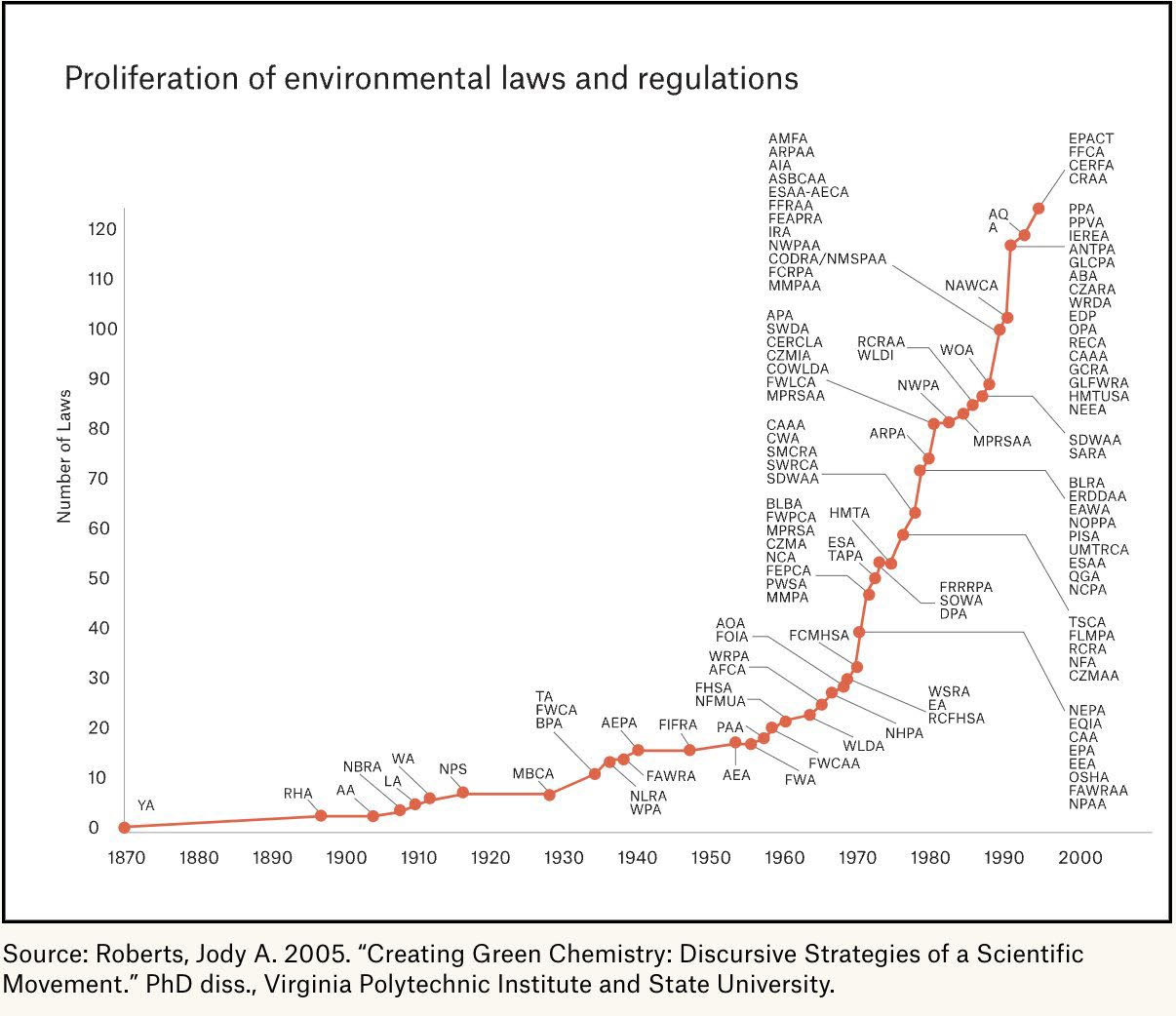

Some regulation is necessary with any technology, but nuclear construction regulations across the West have become cumbersome due to decades of hyperfocus on safety and environmental standards, largely thanks to so-called environmental groups who protested new nuclear to deliberately drive up costs and build times with lengthy regulation processes.

For example, an anti-nuclear activist group in Britain that campaigns against a proposed new reactor at Sizewell C nuclear power station recently launched and lost a legal challenge against the energy provider EDF Energy. The anti-nuclear group argued that putting a new reactor at the existing power plant site is not ecologically sound. Yet the environmental statement the Sizewell C team put together in 2020, which is 203 pages long, demonstrates that the site will have a net gain for biodiversity. EDF’s environmental plan also involves building a new 11-acre marsh harrier wetland habitat for wildlife - a mosaic of wet reedbed with 20-30% open water and 1km of lowland ditches.

A year after they launched the legal challenge, a Judge dismissed it, stating that the group’s arguments were "totally without merit." For the anti-nuclear group, the year of stalling and required paperwork, a two-day hearing, and an ongoing appeal process amount to a victory. This process will already have added to the cost and build time of Sizewell C. A 203-page environmental review had already taken place.

Because of stunts like this, despite cross-party and public support for nuclear energy, it’s hard to get new infrastructure projects off the ground in the UK. People lose hope in the technology when they see constant delays (without necessarily knowing what’s causing the hold-ups). This has led to the widely believed myth that nuclear power plants are inherently slow to build.

The West has become somewhat trigger-happy about regulation in general. In the US, ‘regulatory paralysis’ has made high-speed rail virtually impossible to build, with complaints that “the Global Warming Solutions Act of 2006 and subsequent add-on legislation, demand absurd levels of analysis and predictions, right down to how many molecules of [carbon dioxide] each phase of the project will generate or offset, from initial construction to decades in the future”. Over-regulation has also potentially prevented the country from being a world leader in 5G technology instead of China and has even made childcare more expensive without improving it.

In the UK, the cumbersome and slow planning process delays much-needed new housing, regulation prevents crucial clinical research and erodes trust in doctors. I think you get the picture.

Let’s look at energy. South Korea’s APR-1400 reactors are highly reliable, with three times fewer capacity losses than in the US and six times lower than the UK’s reactor fleet, but if the country’s Korea Electric Power Corporation (KEPCO) wanted to build a nuclear power station in Britain, it would take much longer than the few years it takes at home.

First, the company would have to complete an assessment where the design is submitted to the Office for Nuclear Regulation (ONR) and the Environment Agency (EA). They assess the design for safety, environmental impact, and waste management, which takes around four years. Next, they’d have to apply for planning permission. Then, the application would need to be approved by the local Council, which means having the support of residents and regional politicians.

Since Britain created the laborious approval process for nuclear reactors, only four reactor designs are currently being assessed, and they are small modular reactor (SMR) designs. The APR-1400 isn’t on the approved list, and even if KEPCO went through the cumbersome regulatory process, there’s no guarantee that the reactor would pass or that the company wouldn’t have to make costly design changes, which is a disincentive.

Although some regulations have made nuclear safer, most act as bottlenecks that prevent us from using this life-saving technology, and the lengthy time constraints and mounds of paperwork required by the regulatory process turn off investors in droves. In 2019, the Japanese company GE Hitachi Nuclear Energy lost £2 billion after failing to secure the necessary government commitment to build at the Wylfa site in Wales and ultimately gave up on the project. The greatest irony is that standards for nuclear builds are stricter than those for building coal-fired power stations - all in the name of safety. We have anti-nuclear activists to thank for that.

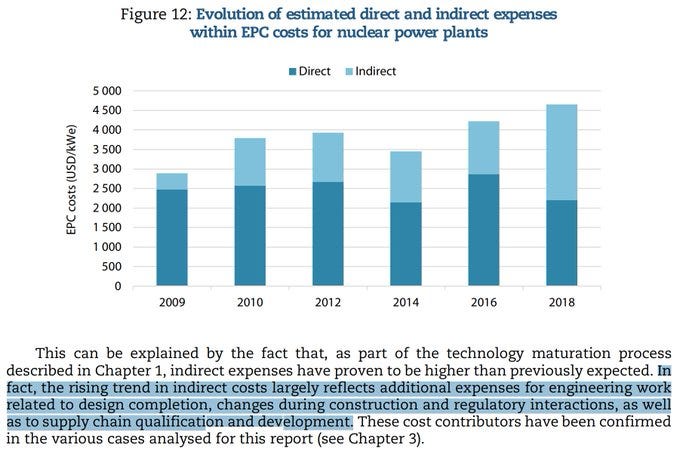

The new reactors under construction in the UK are European pressurised water reactors (EPRs). However, French energy company EDF’s reactors only gained approval in the UK after making thousands of changes to the reactor design used in France. People like to blame the reactor design - the EPR - but as The NY Times reported: “EDF placed additional blame for the delays and cost overruns on Britain’s nuclear regulations. To meet the requirements… the original design would need 7,000 changes, including 35% more steel and 25% more concrete.”

As well as the need to source and pay for extra materials which the reactors do not require to function well in France, where almost 70% of the country’s electricity comes from nuclear energy, this also means that lessons EDF have learned about reactor design cannot easily be applied in the UK. The changes also disrupt the process of standardisation. This leads to further delays as the reactor is essentially built from scratch in an amended way from the original fleet in France. That's a problem because productivity gains come from practice.

A simple question is why all nuclear reactors built in the UK need approval from the ONR when South Korea's APR-1400 has already been approved as safe in the US and parts of the EU. Medicines recognised as safe in the EU, US, or Japan are often automatically approved as safe in the UK. We do not test them according to our standards; we trust this has already happened overseas. Why not apply the same approach to nuclear reactors? If we were to automatically approve designs accepted as safe elsewhere by respected regulators like the NRC, this would shorten the time it would take to bring a South Korean reactor to market, and avoid unnecessary design changes and additional costs and build times.

In the US, a new reactor has to be approved by the federal Nuclear Regulatory Commission (NRC). This process can take up to five years, inevitably increasing costs. Twelve states also have independent conditions restricting new nuclear construction. Some regulatory increases to address safety concerns after Three Mile Island were reasonable, but many had nothing to do with safety. An analysis by EPRI found that nuclear-grade components were, in some cases, 50 times more expensive than industrial-grade ones, like in the case of 75 mm stainless steel gate valves. You might assume that nuclear-grade components must be necessary, but they’re not.

Analyst Charles Komanoff’s comprehensive paper on power plant cost escalation covers this in detail. He writes:

“One key indicator of regulatory standards, the number of Atomic Energy Commission (AEC) and Nuclear Regulatory Commission (NRC) ‘regulatory guides’ stipulating acceptable design and construction practices for reactor systems and equipment, grew almost seven-fold, from 21 in 1971 to 143 in 1978. Professional engineering societies developed new nuclear standards at an even faster rate (often in anticipation of AEC and NRC). These led to more stringent (and costly) manufacturing, testing, and performance criteria for structural materials such as concrete and steel, and basic components such as valves, pumps, and cables. Throughout the 1970s, these changes approximately doubled the amounts of materials, equipment, and labour and tripled the design engineering effort required per unit of nuclear capacity, according to the Atomic Industrial Forum.”

It’s absurd that these nuclear-grade components are required when they are not necessarily higher performing than conventional components. Reinforcing steel in nuclear-grade concrete is the same material used in conventional concrete. The same is true for valves. The increased burden of paperwork and testing impacts morale and slows the construction process down. The paperwork required to meet quality certification regulations also increases costs by reducing market competition among manufacturers, who have no incentive to manufacture nuclear-grade components since they require a lot more paperwork. This hits the supply chain, making obtaining components harder and increasing prices.

The simple solution here is to ease these unnecessary regulatory frameworks, which do not benefit the environment at all. Several countries with multiple nuclear sites that have operated safely for years show how regulation can engender safety without holding back vital technology.

We need to leave building large infrastructure projects to engineers, not lawyers. Western countries must reregulate nuclear power to build nuclear power plants quickly and at cost.

2. Standardise

One of the reasons South Korea’s costs are low compared to the UK is because they build fleets of reactors rather than one at a time. Every time they build a reactor, they learn something new and can apply it to future projects. The same team builds the same reactor repeatedly, which means they get better and faster. This is known as standardisation or learning by doing.

Standardisation has lowered the costs of building nuclear power plants in France and the US, and the UAE’s Barakah plant employed the same approach and succeeded in building four reactors in under a decade. Between 1970 and 2000, France built 58 nuclear reactors at an average of 2.6 years faster than US plants, which was partly due to a high degree of standardisation.

3. Consider the supply chain

Another factor that influences build times is how easy it is to source materials and tools. For example, large nuclear reactors require single-forged pressure vessels, and before 2007, there was only one operational forge, which slowed down the global construction of new power plants. As a result of this, several countries decided to develop their own heavy forging apparatus. Now, China, Japan, France and Russia operate heavy forges. South Korea, the Czech Republic, India and the UK are attempting to follow suit. China has the most forges and plans to build more, which will help to speed up the rate at which they build new nuclear power plants.

It’s also a good idea to consider the supply chain before committing to a large new infrastructure project, to ensure the materials and tools are available. Changing the regulatory frameworks that restrict materials to nuclear-grade only should make a difference here.

4. Recruit workers, develop skills

Nuclear workers are climate heroes. I coined this phrase a few years ago, and I stand by it today.

The International Atomic Energy Agency (IAEA) has reported that investments in nuclear power produce the most considerable economic multiplier effect of any clean energy source. Nuclear power creates about 25% more employment per unit of electricity than wind power, while workers in the nuclear industry earn one-third more than those in the ‘renewables’ sector. These jobs are well-paid, long-term and predominantly local.

Many countries globally face the challenge of recruiting more people into STEM (science, technology, engineering and mathematics) vocations. One simple step to help remedy this is to remove barriers to training and qualifications by offering apprenticeships, removing loans and fees, and guaranteeing work at the end of the study period by committing to new infrastructure projects so that jobs are readily available.

Currently, the 77,000 civil nuclear jobs in the UK mean that employment in nuclear is the highest it has been in at least 20 years, but a fifth of the workforce is aged 55 or over, which leaves a skills gap. Hinkley Point C has created thousands of jobs on-site and nationwide, and Sizewell C will follow suit. The Nuclear Skills Strategy Group's Nuclear Workforce Assessment has forecasted that between 3,200 and 4,800 new workers will be needed yearly to meet the demand from new projects. To help address this, the UK government has just announced investment in a recruitment drive to create a nuclear workforce.

A report by the British Science Association assessing insights into young people’s attitudes towards nuclear energy found that young people in Britain are open to careers in nuclear energy, but they don’t feel they are informed about it. The research showed that 14- to 18-year-olds felt more informed about renewables and fossil fuels than nuclear energy, including through schooling. Young people are also highly concerned about climate change, and want to learn more about how nuclear power could help to address it.

Almost two-thirds (64%) of young people said they would be interested in careers in nuclear, and 70% believed that a career in the nuclear industry would be “challenging” rather than “uninspiring” (6%). 58% said such a role would be “interesting” rather than “boring” (15%). These are substantial statements, which, if leveraged, could create the nuclear workforce Britain needs to get back on track energy-wise.

People who care about the planet’s future and want to make a difference will achieve more by working in the nuclear sector rather than blocking roads. Ideally, the formal education process should inform them of this, but it is currently woefully inadequate when teaching electricity generation and climate solutions. In Britain, simply adding these subjects to the curriculum would address the problem.

In France, where the nuclear sector is the third-largest industry after the aeronautics and automotive sectors, the public already has a positive view of vocations in nuclear. However, as with other Western countries, France suffers from a skills mismatch - France's manufacturing, construction, engineering and IT industries struggle to obtain the workers they need. The French government is also attempting to entice and recruit workers to get power plants built and has launched a construction drive that has not been seen in nuclear since the 1970s. This includes a disturbance allowance equal to two months of salary to change residence, a ‘discovery pack’ to help workers familiarise themselves with the location they will be working in, a financial ‘mobility pack’ to help find accommodation and a job for spouses, as well as benefits to cover childcare and schooling.

5. Domestically commercialise

Due to its size, South Korea doesn’t have the power to sustain a globally relevant nuclear industry on the back of its domestic market alone, like China or the US can. Therefore, it has maximised an advantage by developing an efficient reactor design that it exports to countries like the United Arab Emirates. By focusing on manufacturability, South Korea has succeeded with nuclear energy at home and in the UAE. The country plans to export to the Netherlands, Africa, Kazakhstan, and maybe even the UK. Countries in a similar situation to South Korea would do well to follow this route: the country’s scaling up of nuclear energy coincided with becoming the world’s 11th largest economy by the mid-1990s.

A note on innovation

Unless you’re building a small modular reactor, there’s no need to change existing large-scale nuclear reactors. Materially-efficient reactor designs already exist, and can be built quickly. There is, however, room for innovative ideas that might shape the future of new nuclear projects, such as printing 3D parts for nuclear plants, transitioning coal sites to nuclear sites, and improving efficiency at power plants by employing AI tools.

The required changes may seem complicated, but in practice, they are straightforward. Pick a good design, remove regulatory barriers, check the supply chain, inform and incentivise workers, and proceed to build fleets at a time. It’s not rocket science.

Nuclear energy is at the forefront of the fight for clean air, energy security, a healthy planet and the decarbonisation of electricity grids. Western countries have overcomplicated the process of building large new infrastructure projects that are needed to protect and advance civilisation. We can reset this burdensome approach to building nuclear power plants. We can learn from the giants of the world, and then we can go further. Imagine a hyper-efficient way to build reactors quickly: a gigafactory printing nuclear reactors, one after the other. Whether any country will propel humankind forward by setting and achieving such ambitions remains to be seen, but a future of energy abundance and resilience is up for grabs, if we choose to permit it.

Anyone who thinks nuclear “is just too expensive,” should read this article. South Korea, France, and China are not going to sit around wetting their pants over imagined nuclear energy fears. It’s time to get real.

Zion, Great writing, with supporting facts. I posted it on LinkedIn to get more readers.